⚙️ Slewing Bearings – High-Precision Slew Ring Bearings for Industrial Applications

🧭 What Is A Slewing Ring?

-

A Slewing Ring (also known as a Slew Ring Bearing or Slewing Bearing) is a large, high-precision bearing designed to support axial, radial, and moment loads simultaneously.

-

Unlike traditional bearings that allow only rotational movement, slewing rings enable slow, smooth, oscillating, and rotational motion under heavy loads.

-

They are commonly used in cranes, excavators, wind turbines, industrial robots, and medical equipment, where both rotation and stability are essential.

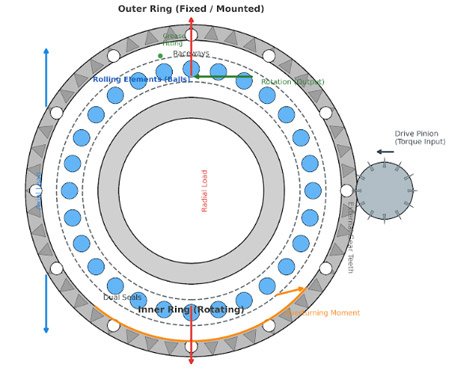

- Inner ring and outer ring – one of which usually has gear teeth.

- Rolling elements (balls or rollers) for smooth movement.

- Seals and spacers to retain lubrication and protect against contaminants.

The unique design allows rotation or oscillation of heavy or unbalanced loads with high precision and minimal friction — making it a critical component in modern mechanical systems.

⚙️ Industrial Slewing Bearing Types

Kavitsu Bearing manufactures a wide range of Slew Ring Bearings tailored for specific industrial applications. Each type has its unique design, load capacity, and performance characteristics.

-

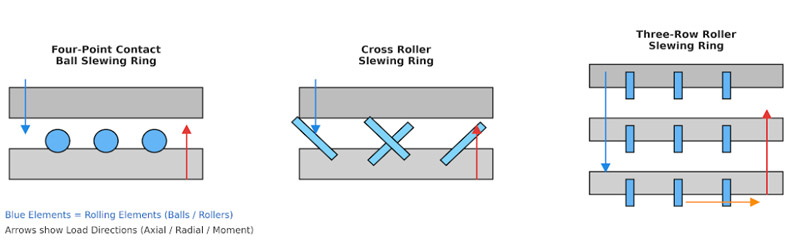

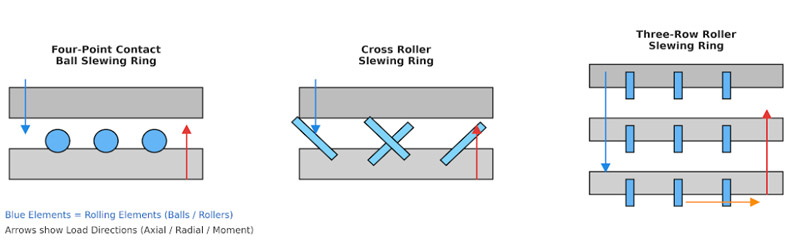

🔹 1. Four-Point Contact Ball Slewing Ring

Designed with a single row of balls that contact the raceway at four points.

Handles combined axial, radial, and moment loads efficiently.

Compact and lightweight, suitable for light to medium-duty applications like cranes, excavators, and turntables.

-

🔹 2. Cross Roller Slewing Ring

Contains cylindrical rollers arranged in a crisscross pattern.

Provides high rigidity and precision with minimal friction.

Ideal for robotics, medical imaging systems, and aerospace where accuracy is critical.

-

🔹 3. Three-Row Roller Slewing Ring

Features three independent rows of rollers for maximum load-carrying capacity.

Each row handles different load directions — axial, radial, and moment.

Perfect for heavy-duty applications like construction cranes, offshore platforms, and wind turbines.

-

🔹 4. Single Row Ball Slewing Bearings

Simple and compact design with single ball row raceways.

Cost-effective and easy to install.

Common in material handling systems, packaging machines, and rotating platforms.

-

🔹 5. Double Row Ball Slewing Bearings

Two rows of ball bearings provide enhanced load distribution.

Suitable for medium to heavy-duty machinery, offering smooth operation and long service life.

Used in aerial lifts, excavators, and conveyors.

-

🔹 6. Three Row Roller Slew Ring Bearings

Engineered for ultra-heavy load handling.

Each row of rollers bears a specific type of load (axial, radial, or moment).

Delivers unmatched strength and stability for marine cranes, drilling rigs, and wind turbines.

2D schematic comparison of the three major Slewing Bearing types

✅ Image Classification :

- Four-Point Contact Ball Slewing Ring

- Cross Roller Slewing Ring

- Three-Row Roller Slewing Ring

✅ Visual Elements:

- Color-coded rolling elements (blue)

- Simplified raceways

- Directional load arrows (axial, radial, and moment)

- Clear labels for each type

⚙️ How Does a Slewing Ring Work?

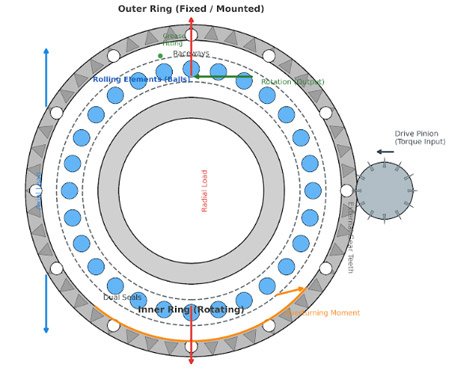

A Slew Ring Bearing works by combining rotational movement with the ability to withstand axial and radial forces simultaneously.

-

When the inner or outer ring rotates, the rolling elements move between the raceways, providing smooth motion and distributing loads evenly.

-

In geared versions, internal or external gear teeth transmit torque between the rotating and stationary structures.

This design ensures:

• Low friction and precise movement, even under extreme load.

• High torque transfer with minimal backlash.

• Stable rotation, whether continuous or intermittent.

• Lubrication and seals play a critical role in maintaining performance by minimizing wear and preventing contamination.

⚙️ What Materials Are Used In Slewing Bearings?

High-quality Slewing Bearings are engineered with carefully selected materials to ensure durability, performance, and reliability under demanding conditions.

- 🔹 Rolling Elements

Made from hardened chromium steel for strength and wear resistance.

Precision-ground surfaces ensure smooth rolling and uniform load distribution.

- 🔹 Inner and Outer Ring

Manufactured from forged alloy steel or 42CrMo4 / 50Mn steel, heat-treated for toughness.

Hardened raceways enhance fatigue strength and longevity.

- 🔹 Spacer / Cage

Separates rolling elements and reduces friction.

Made from nylon, brass, or steel, depending on operating conditions.

- 🔹 Seals

Synthetic rubber or nitrile seals prevent dirt, dust, and moisture from entering.

Maintain lubrication and extend bearing life.

These materials ensure exceptional load capacity, corrosion resistance, and precision, making Kavitsu’s Slew Ring Bearings suitable for both industrial and outdoor environments.

⚙️ Considering Factors for Slew Roller Bearing Design

- Accuracy: Precision in manufacturing determines smoothness and stability.

- Magnitude & Direction of Loads: Must handle axial, radial, and tilting moment loads.

- Permissible Operating Temperature: Material and lubrication should withstand varying conditions.

- Vibration: The design must minimize vibration for consistent motion.

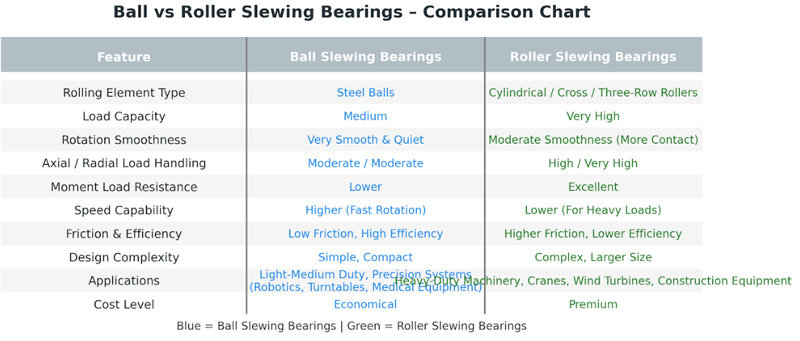

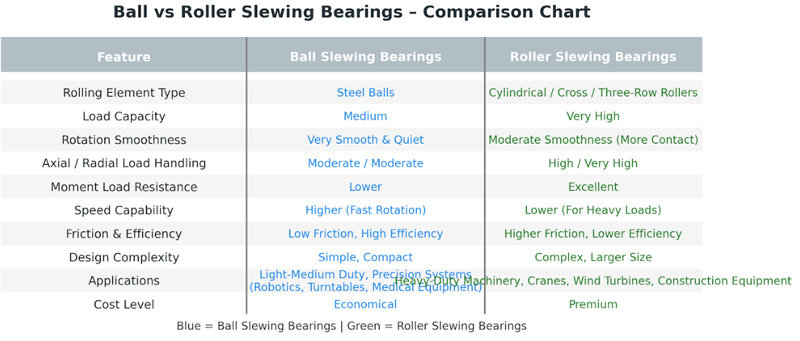

- Operating Speed: Determines bearing type — ball bearings for high speed, rollers for high load.

- Sealing: Essential to protect against environmental contaminants.

- Raceway Design: Affects load capacity and rotational accuracy.

- Lubrication: Grease or oil lubrication reduces wear and friction.

- Gear Arrangements: Internal, external, or gearless options available depending on torque and space requirements.

Kavitsu engineers optimize each Slewing Bearing Design to ensure maximum load handling, smooth rotation, and long operational life.

⚙️ What Are The Advantages Of Roller Slewing Bearings?

- 🔹 1. High Load Capacity

Roller-type slewing bearings can handle massive axial and radial loads, as well as overturning moments, due to their multiple contact lines.

- 🔹 2. Smooth Rotation

Precision-machined raceways and rolling elements ensure consistent rotation with minimal friction and noise.

- 🔹 3. Compact Design

Slewing bearings integrate bearing and gear functions into one compact unit, reducing overall system size and complexity.

- 🔹 4. Application Versatility

From cranes and excavators to robots and wind turbines, these bearings are suitable for rotary, oscillating, and positioning movements.

- 🔹 5. Easy Mounting & Integration

Designed with bolt holes on both inner and outer rings, allowing simple installation and alignment flexibility.

🏭 Slewing Bearing Application Industries

- Construction and Heavy Equipment: Used in cranes, excavators, loaders, and drilling rigs for rotation and load support.

- Renewable Energy: Integral to wind turbines and solar tracking systems for precise positioning.

- Material Handling & Conveyor Systems: Enable 360° rotation in conveyors, stackers, and turntables.

- Robotics & Automation: Provide high-precision movement in robotic joints and assembly systems.

- Industrial Machinery: Used in packaging, mining, and marine equipment where stability and motion control are vital.

- Aerospace & Defense: Applied in radar systems, aircraft weapon mounts, and satellite tracking systems.

- Medical Equipment: Used in CT scanners, surgical robots, and imaging systems for silent and stable motion.

- Entertainment Industry: Supports amusement rides, stage equipment, and rotating displays, providing smooth and safe motion.

🏆 Why Choose Kavitsu for Slewing Bearings

Kavitsu Bearing, headquartered at 📍 K-3/2/2, Additional MIDC Area, Satara - 415004, Maharashtra, India,

is one of India’s leading Manufacturers, Suppliers, and Exporters of Slewing Bearings and Slew Ring Bearings.

- Comprehensive Product Range: From four-point contact ball bearings to three-row roller slew rings.

- Precision Engineering: Manufactured with CNC and heat-treatment processes ensuring reliability.

- Global Standards: Designed as per ISO and DIN standards for international applications.

- Customized Solutions: Tailor-made slewing bearings for specific load, speed, and environmental conditions.

- Dedicated Support: Expert guidance for design, selection, and after-sales service.

- Quality Assurance: Every bearing undergoes strict inspection and testing for performance and endurance.

For high-performance, long-lasting, and efficient Slewing Bearings, trust Kavitsu Bearing - where engineering meets reliability.

📧 Email: response@slewringbearings.com

📞 Phone: +91 9096469696

📍 Address: K-3/2/2, Additional MIDC Area, Satara - 415004, Maharashtra, India