⚙️ Slew Drives – Precision Slewing Solutions for Rotation and Positioning Applications

🧭 What Is A Slew Drive?

-

A Slew Drive (also known as a Slewing Drive or Slewing Gear Drive) is a complete motion control system that combines a slewing bearing, worm gear or planetary gear, and housing unit into one compact assembly.

-

It is designed to transmit rotational movement and torque to support heavy radial, axial, and tilting moment loads while enabling precise angular positioning.

-

Slew drives are used in systems that require controlled rotation, stability, and torque transmission — such as solar tracking, cranes, wind turbines, industrial automation, and aerial platforms.

-

At its core, a slew drive simplifies complex rotary motion into an integrated, self-contained unit — reducing design time and maintenance while ensuring durability and reliability.

⚙️ Types of Industrial Slew Drives

Kavitsu Bearing manufactures a broad range of Slew Drives engineered for varied torque, speed, and load requirements. Each type is optimized for different mechanical systems and operational conditions.

-

🔹 1. Worm Gear Slew Drive

Uses a worm and worm wheel arrangement similar to a worm gearbox.

Provides self-locking capability, ensuring safety in holding loads even when power is off.

Ideal for solar trackers, cranes, and lifting platforms.

-

🔹 2. Planetary Slew Drive

Features a planetary gear system integrated with the slewing ring.

Offers higher efficiency and torque density than worm drives.

Suitable for heavy-duty machinery, robotics, and wind turbines where smooth, continuous rotation is needed.

-

🔹 3. Dual-Axis Slew Drive

Allows rotation on two perpendicular axes simultaneously.

Commonly used in dual-axis solar trackers and radar positioning systems for precision alignment.

-

🔹 4. Enclosed / Fully Sealed Slew Drive

Designed for harsh outdoor environments (dust, rain, temperature variations).

Equipped with IP-rated sealing systems for superior protection.

Commonly found in renewable energy and mobile machinery.

-

🔹 5. Customized Slew Drives

Kavitsu offers tailor-made slew drives for unique industry applications, with options for manual, hydraulic, or electric actuation and custom torque configurations.

Diagram illustrates the three main designs clearly:

🟡 Worm Gear Slew Drive – Self-locking, safe for heavy lifting

🔵 Planetary Slew Drive – High-efficiency, smooth motion

🟣 Dual-Axis Slew Drive – Precision two-axis tracking

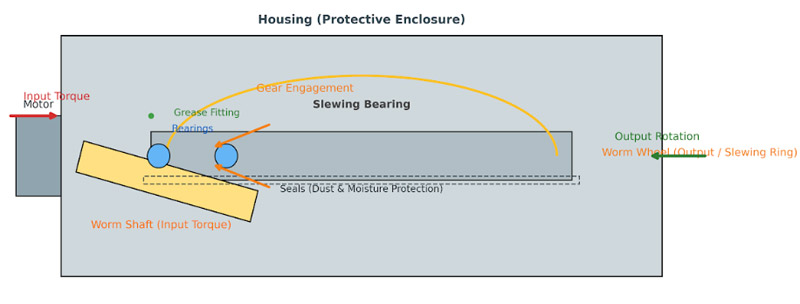

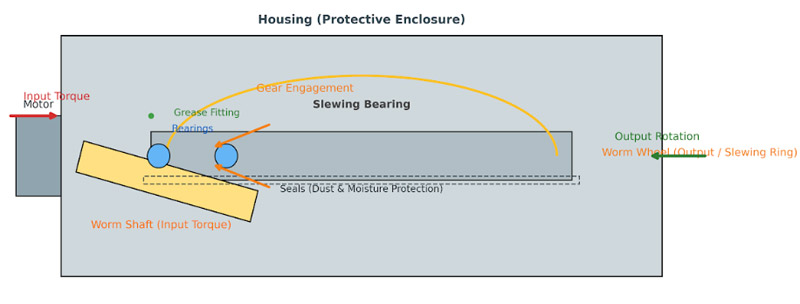

⚙️ How Does a Slew Drive Work?

A Slew Drive operates by converting input torque into rotational motion using an internal gear mechanism combined with a slewing bearing.

-

In a worm-driven slew drive, the worm shaft (input) meshes with a worm wheel integrated into the slewing bearing. As the worm rotates, it transfers torque to the slewing ring, producing rotational output while also resisting back-driving — a feature known as self-locking.

-

In a planetary slew drive, the input shaft drives a set of planet gears that revolve around a central sun gear, transferring torque evenly to the output ring.

-

The entire system is enclosed in a protective housing, ensuring smooth, precise rotation even under high loads or demanding environments.

Add image here: (how_slew_drive_works_diagram.png)

Diagram explains:

• Motor (input source)

• Worm Shaft transmitting torque

• Gear engagement with Worm Wheel / Slewing Ring

• Slewing Bearing housed inside the casing

• Output rotation direction

• Bearings, grease fitting, and seals

⚙️ What Materials Are Used In Slew Drives?

Each component of Kavitsu’s Slew Drives is crafted from high-grade materials to ensure long life and performance reliability.

- 🔹 Housing

Made from cast iron or alloy steel, machined for high precision.

Provides rigidity and protection for internal components.

- 🔹 Gears

Hardened steel worm or planetary gears with optimized surface finish for minimal wear.

- 🔹 Slewing Bearing

Integrated four-point contact ball bearing or cross roller bearing for load handling.

- 🔹 Seals

High-quality nitrile or silicone rubber seals to prevent dust and moisture ingress.

- 🔹 Lubrication

Filled with EP-grade synthetic lubricants to minimize friction and heat generation.

These material choices ensure Kavitsu’s slew drives perform reliably across industrial, mobile, and renewable energy applications.

⚙️ Considering Factors for Slew Drive Design

- Load Capacity: Must handle combined axial, radial, and moment loads.

- Speed & Torque: Determines gearbox ratio and motor compatibility.

- Self-Locking Requirement: Crucial for safety in load-holding applications.

- Operating Environment: Indoor, outdoor, temperature, or exposure conditions.

- Sealing & Lubrication: Essential for protection and long service life.

- Mounting Position: Horizontal, vertical, or inclined orientation.

- Accuracy & Backlash: Impacts positioning precision in automation and solar tracking.

Kavitsu engineers design each Slew Drive for optimal performance across these parameters, ensuring precision, safety, and durability.

⚙️ What Are The Advantages of Slew Drives?

- 🔹 1. Compact & Integrated Design

Combines bearing, gear, and drive into a single, easy-to-mount unit — saving space and simplifying system design.

- 🔹 2. High Torque Output

Worm and planetary gear designs provide superior torque multiplication, enabling the drive to handle massive loads.

- 🔹 3. Self-Locking Capability

Prevents reverse motion, ensuring safety in cranes, lifts, and solar trackers.

- 🔹 4. Easy Installation

Bolt-on housing with multiple mounting holes simplifies assembly and alignment.

- 🔹 5. Maintenance-Friendly

Sealed housing minimizes dust ingress and retains lubrication, requiring minimal maintenance.

- 🔹 6. Versatile Applications

Can be driven by electric, hydraulic, or manual input, offering flexibility across industries.

🏭 Slew Drive Application Industries

- 1. Renewable Energy: Used in solar tracking systems and wind turbines to achieve precise sun or wind alignment.

- 2. Construction & Heavy Equipment: Essential in cranes, excavators, drilling rigs, and aerial lifts for stable, load-bearing rotation.

- 3. Material Handling: Powers conveyors, lifting tables, and rotating platforms with reliability.

- 4. Robotics & Automation: Provides controlled, high-precision rotation for robotic joints and positioning arms.

- 5. Military & Aerospace: Used in radar systems, missile launchers, and defense turrets due to compactness and stability.

- 6. Industrial Machinery: Applied in packaging, mining, and processing machines where torque and control are vital.

- 7. Marine & Offshore Applications: Resistant to saltwater and corrosion; used in ship cranes and drilling platforms.

🏆 Why Choose Kavitsu for Slew Drives

Kavitsu Bearing, located at 📍 K-3/2/2, Additional MIDC Area, Satara - 415004, Maharashtra, India, is India’s trusted Manufacturer, Supplier, and Exporter of Slew Drives and Slewing Bearings.

🔹 Why Kavitsu Leads the Industry

- In-house Design & Manufacturing: Complete control over quality and precision.

- Custom Configurations: Electric, hydraulic, or dual-axis options available.

- Global Standards: Manufactured as per ISO and DIN specifications.

- Durability & Safety: Each unit undergoes torque, load, and sealing tests.

- Global Supply Network: Serving industries across India, Europe, and Asia.

- Expert Technical Support: Tailored guidance for selection, installation, and maintenance.

For reliable, high-performance Slew Drives, choose Kavitsu Bearing — a brand known for innovation, precision, and engineering excellence.

📧 Email: response@slewringbearings.com

📞 Phone: +91 9096469696

📍 Address: K-3/2/2, Additional MIDC Area, Satara - 415004, Maharashtra, India